Tailored Metalworking Fluids for Precision Performance

Tailored Metalworking Fluids for Precision Performance

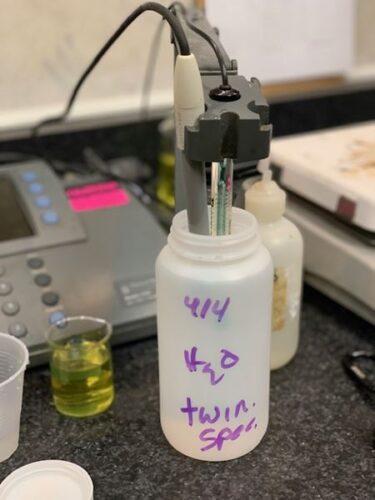

At Twin Specialties, we understand that no matter how hard you try, sometimes stock metalworking fluids just can’t meet the demands you require for optimal manufacturing performance. That’s why we offer custom blended metalworking fluid formulations—engineered specifically to meet the demands of your machines, materials, and production goals.

Whether you’re machining stainless steel, drawing titanium, or grinding cast iron, we help you fine-tune your metalworking fluids for better performance, improved tool and coolant life, cleaner operations, and fewer issues in the factory. Our team works directly with you to evaluate your current fluids, diagnose problems, and deliver a better-performing blend—quickly and cost-effectively.

When Off-the-Shelf Isn’t Enough

Standard fluids work for standard jobs, but you should consider a custom formulation if you’re experiencing any of the issues listed below:

- Tool wear or breakage

- Rust or corrosion on parts or equipment

- Overheating or off-spec parts during machining

- Foaming or inconsistent coolant flow

- Bacterial growth or foul odors

- Skin irritation or misting concerns

- Or you’re simply not happy with your current supplier’s service or pricing

…it’s time to consider a custom solution.

At Twin Specialties, our formulation experts identify what’s going wrong and craft a tailored coolant, lubricant, or metalworking fluid that meets your exact operational needs.

Our Custom Fluid Development Process

Our approach is hands-on and rooted in real-world applications. Here’s how it works:

- Evaluate Your Current Fluid

We analyze what you’re currently using and gather feedback on performance. - Understand Your Operation

We consider your materials, machines, processes (CNC, grinding, stamping, drawing, etc.), and goals. - Identify the Issue

Whether it’s rust, foaming, bacteria, cost, or performance—we find the root cause. - Optimize the Formula

We may:

- Adjust oil content to improve lubricity

- Add biocides to fight bacteria

- Introduce specialty additives to improve corrosion resistance, reduce mist and/or foaming, or enhance stability

- Deliver a Custom Solution

We provide a unique, ready-to-use fluid, often based on proven base formulas we’ve adapted for similar needs.

Designed for a Wide Range of Metalworking Applications

Our custom blended fluids are used in:

- CNC machining (milling, turning, drilling, tapping)

- Grinding (surface, ID, OD, centerless)

- Drawing (forming, stamping, blanking, tube bending, perforating)

- Sawing and quenching

- And other precision metal fabrication operations

No matter the metal—aluminum, stainless, titanium, carbon steel, copper—we’ll recommend a formulation that fits your process and your budget.

Why Choose Twin Specialties?

- Decades of Experience in metalworking fluid formulation and field troubleshooting

- Fast Turnaround – Many custom blends can be developed in days, not weeks

- Performance-Driven Results – We solve problems like rust, foaming, tool failure, and bacterial growth

- Flexible Quantities – Whether you need one pail or a truckload totes, we’ll scale to your shop size

- Personalized Support – We’re known for our responsive service and real-world expertise

Don’t Settle for One-Size-Fits-All

If your current fluid isn’t meeting your specifications for the job—or if your supplier isn’t either—Twin Specialties can help. Our custom metalworking fluid formulations are developed to solve problems and deliver long-term value, not just fill a drum.

Contact us today to speak with a technical specialist and request a custom fluid evaluation.

Proudly blending fluids for shops and manufacturers across the United States and worldwide.